Basa Fish Industry: Vinh Hoan Pioneers Circular Economic Model

06 June 2023

Vinh Hoan Corporation, a global basa fish producer in the aquaculture industry, has initiated multiple projects to establish the groundwork for its circular economy model. These endeavors are set to revolutionize and address the existing challenges in farming and processing farmed basa pangasius.

Table of Content

- Innovative projects in Basa pangasius farming and processing

- Utilized waste and byproducts in basa fillet processing

- Constantly expanding the value chain

- Apply high technology

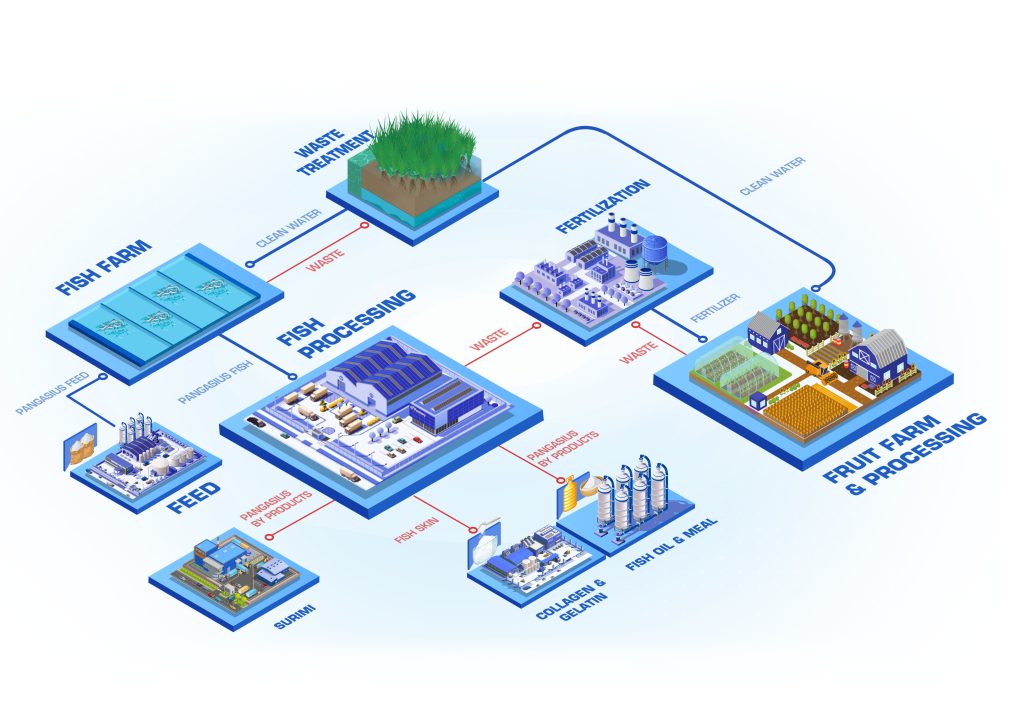

In recent years, the circular economy model has been Vinh Hoan’s share of efforts to mitigate the impacts of the global climate change crisis. By optimizing byproduct usage at every stage of the business cycle, the circular economy model converts the value-chain outputs into inputs for other value-chains.

In Vinh Hoan’s frozen basa fillet processing factories, large amounts of trim meat and bones are considered byproducts; the reuse and utilization of byproducts in aquaculture are crucial. Depending on the level of processing, more than 70% of the fish caught is subjected to further processing before being placed on the market, resulting in approximately 20–80% waste (*). The concept of circular economy is not only applied in processing but also in aquaculture. With a passion for innovation, creativity, and sustainability, Vinh Hoan has begun laying its foundation via several projects to bring this model to life.

Innovative projects in Basa pangasius farming and processing

Vinh Hoan is now implementing the In-Pond Raceway System (IPRS) model, which enables water to be continuously reused in the Basa and Pangasius fish ponds. This approach enhances economic efficiency, meets the industry’s increasing demand for sustainable practices, and optimizes using finite natural resources. Although still in the experimental stage, the IPRS system, with its water reuse model, promises to be a bright spot in aquaculture technology innovation, moving towards a sustainable future for the company’s aquaculture and farming industry.

At Vinh Hoan, total frozen basa fillet processing is utilized, with no waste left behind. The company continuously researches and develops new products from basa and pangasius fish, creating value-added products from byproducts. Since 2011, Vinh Hoan has established the Vinh Wellness division, successfully producing collagen and gelatin from basa fish skin, a high-value product. In addition, the company uses other byproducts in the pangasius processing process as input materials to produce surimi, fish oil, and fishmeal. Hydrolyzed collagen, gelatin, surimi, fishmeal, and refined fish oil are strategic products contributing to Vinh Hoan’s revenue and profits.

Constantly expanding the value chain

Not only frozen basa fish fillet processing, but Vinh Hoan also sees potential in the agricultural sector and aims to become a leading food processing corporation. In early 2021, Vinh Hoan established Vinh Agriculture and acquired Sa Giang food company to expand its value chain. These are two important projects to contribute to the vision of the company’s circular economy model.

Another essential piece of the company’s circular model, which helps reduce environmental emissions, is its investment in Mai Thien Thanh Co., Ltd.. This company processes industrial waste from fish factories and fertilizer production. The company collects waste to produce organic fertilizers and clean soil for agriculture. Byproducts from the processing of agricultural products from Vinh Agriculture are collected and used as input materials for this plant, which recycles them to produce fertilizer.

In addition, Vinh Hoan has made investments in the aqua feed factory to enhance its supply chain in its core areas of basa and pangasius fish farming and processing. Vinh Hoan’s feed factory began operation in the second quarter of 2022. The feed factory has a production capacity of about 350,000 tons per year.

Apply high technology

In addition to our current value chain, Vinh Technology, a division of Vinh Hoan, invests in companies that aim for innovation in technology for aquaculture and agriculture. Last year, Vinh Technology invested in developing the potential of insect meal through Entobel. This Singaporean-based biotech company will produce alternative and sustainable resources for various industries, including animal feed and health.

Madam Truong Thi Le Khanh, founder and chairwoman of Vinh Hoan Corporation, emphasized: “Vinh Hoan inspires innovation to create a sustainable future. Our success will not stop. Our relentless ambition will take us to open more possibilities.”